De Pecker and Fast Pecker Pick & Place robots

The Pecker and Fast Pecker are fully servo-controlled Pick & Place robots that are used for the most diverse packing applications

The main features of the Pecker and Fast Pecker are:

The Pecker Pick & Place robot

The Pecker is a servo-controlled Pick & Place robot that picks up rows or layers of preformed products and packs them in a box, crate or tray. The Pecker is a budget-friendly packer with a small footprint, short installation period and easy central operation via a large color display. Product changes take place in a minimum of time and a packing pattern of a new product can be quickly and easily made by yourself.

A PACKER FOR DIMENSIONALLY STABLE PRODUCTS

Products are preformed per row on the infeed conveyor. Either these rows are picked up by the gripper after alignment and packed in the carton, tray or crate, or the rows are transferred to a transverse belt. This forms layers of products that can be picked and packed.

A PACKER FOR VERY HIGH SPEEDS

At high speeds, several cartons, crates or trays are filled simultaneously. In order not to stop the infeed of products when the cartons, crates or trays are full, a transverse transfer system is used in which the full and empty boxes, crates or trays are changed in no time.

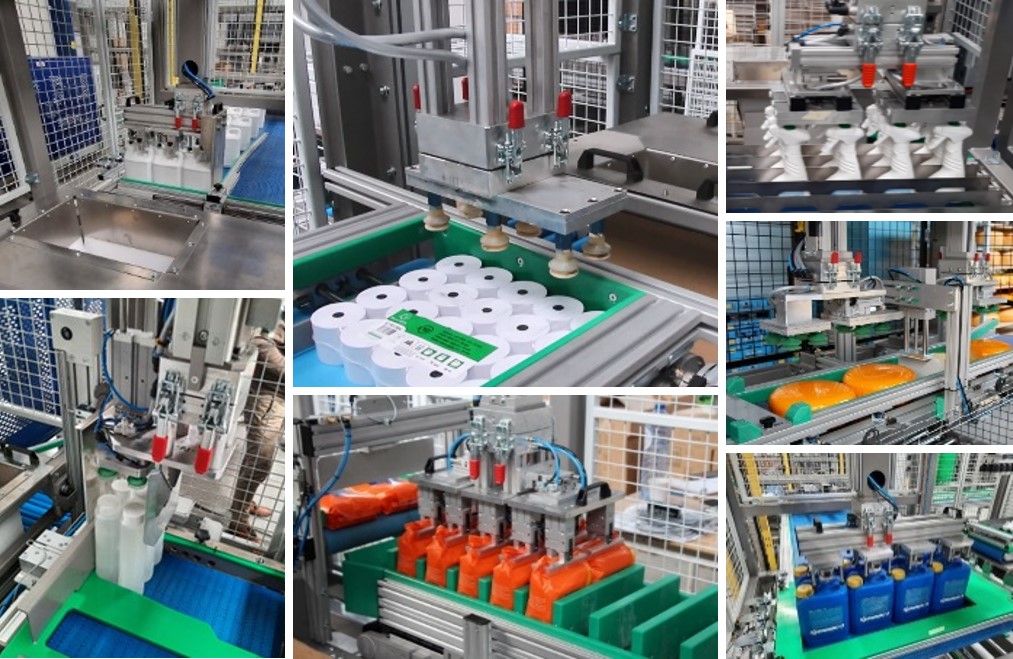

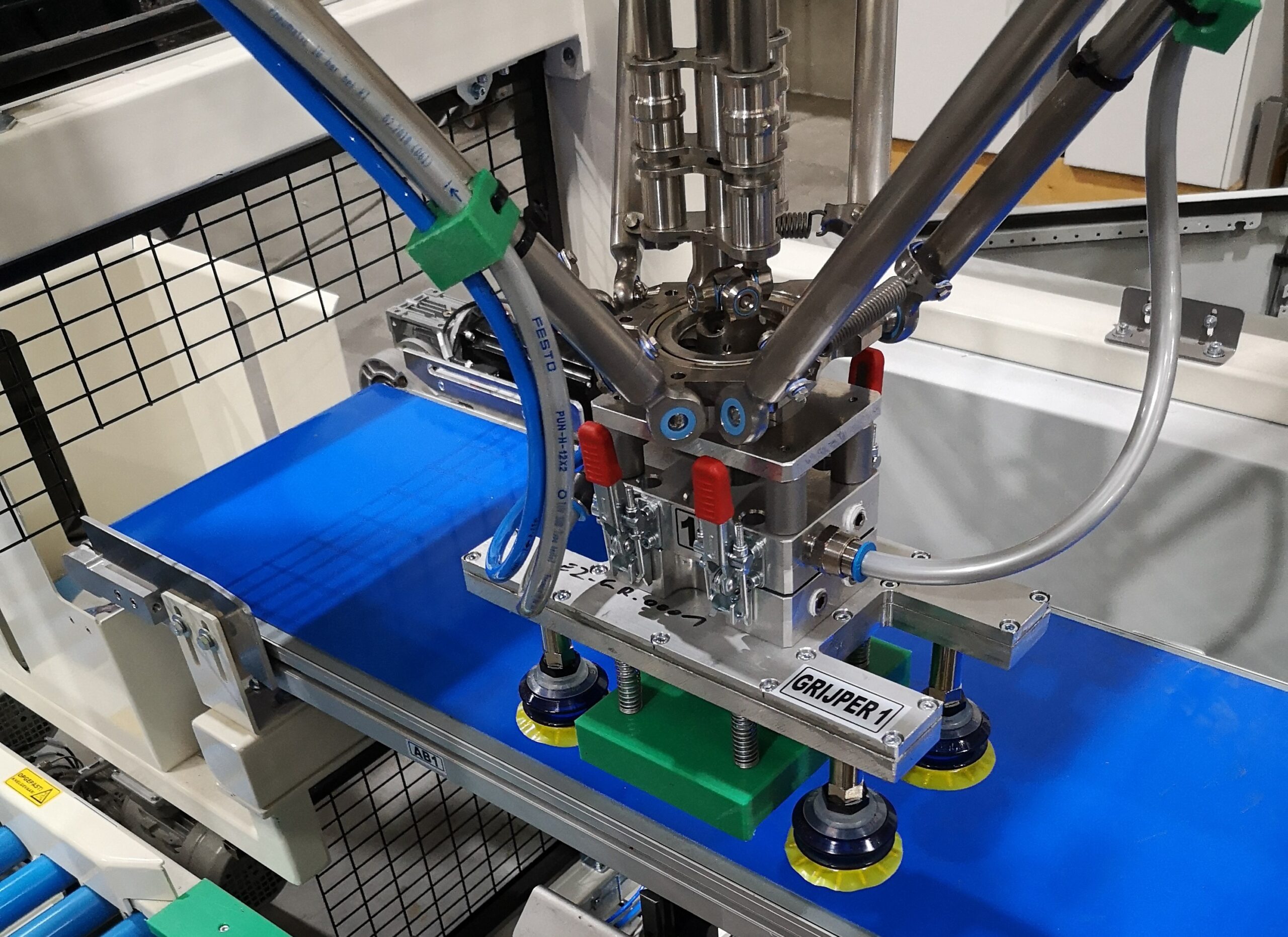

GRIPPERS

Depending on the product to be packed, various grippers are used. Often the products can be picked with vacuum. For this purpose, an internal vacuum passage is foreseen in the flange at the end of the vertical axis so that no pipes need to be disconnected during a gripper change. Depending on the product clamping grippers or a combination of vacuum and clamps can also be used.

UPPER FLAP SPREADER

Often products need to be packed in American boxes. To prevent the products from bumping on or against the upstanding top flaps of the carton while loading, a funnel is used in order to keep the flaps open during loading. This funnel goes up and down during a carton change. The dimension of the funnel correspond to the base of the box. The height adjustment is automatic.

PERIPHERALS

When packing in cardboard boxes, the Pecker is equipped with an automatic carton erector and carton taper. These can be provided by the customer himself if desired. When packing into crates, a crate destacker can be foreseen. A weight check system with reject can be provided. The weight is set automatically when choosing the packing pattern.

After the Pecker, our Spider palletizer is often foreseen to palletize the full cartons, trays or crates on pallets. Pliable crates can also be processed. After the automatic destacking of closed empty crates, they are opened after which the Pecker fills them. The full crates are stacked. One and the same Spider portal robot can unstack the empty closed crates and stack the full ones.

TECHNICAL

A standard servo-controlled manipulator is mounted in a welded, rigid portal frame. The manipulator uses precision gear units that do not allow play on the driven movements. In this way, the accuracy is increased and a maximum of power and speed can be transmitted. The length of the axles is chosen according to the required range of the robot. The manipulator has two or three axes, depending on the project. A gripper rotation is provided when the products need to be packed 90° or 180° after pickup. Double or triple grippers can be mounted on the vertical axis so that several cartons, trays or crates can be filled at the same time. In this way, high speeds can be processed. The grippers are mounted on the vertical axis at the bottom via a flange with quick-change clamps. In this way, the grippers can be changed quickly during a product change, so that almost no changeover time is required. At high speeds, the full and empty cartons, trays or crates are quickly changed via a quick-change system so that the supply and preformation of products does not have to be stopped.

Fast Pecker Delta robot

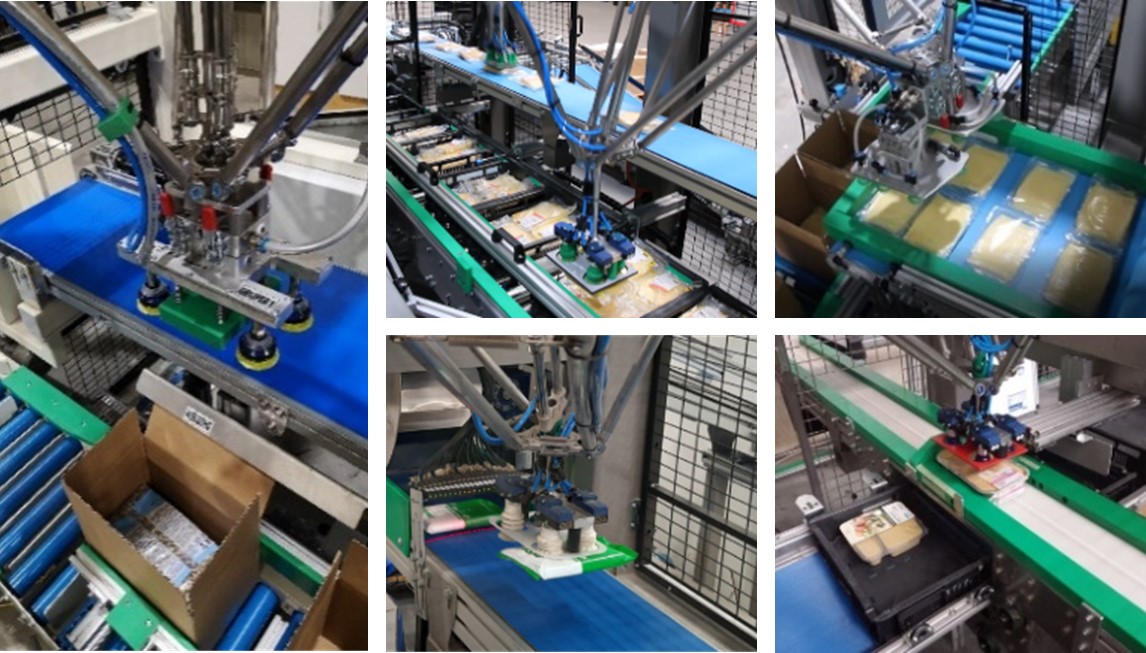

The Fast Pecker is a thoroughbred Pick & Place Delta robot that automatically packs products such as bags, doypacks, trays and all other kinds of non-dimensionally stable products at very high production speeds and according to the desired pattern in cartons, trays or crates. Due to the stainless steel version of the manipulator, the Fast Pecker is also ideal for use in projects within the food industry.

A PACKER FOR NON-DIMENSIONALLY STABLE PRODUCTS

The Fast Pecker picks up the products to be packed from the infeed conveyor without having to stop or align them. This makes the Fast Pecker ideal for packing products such as doypacks, bags, tubes and other non-dimensionally stable products in cartons, trays or crates.

A PACKER FOR VERY HIGH PRODUCTION SPEEDS

The products are picked individually. In order to be able to process high speeds, two products are picked one after the other, after which they are dropped one by one or together. At even higher speeds, two Fast Pecker Delta robots work together: one fills the carton, tray or crate by half and the other fills the rest until it is full.

QUICK-CHANGE SYSTEM FOR GRIPPERS AND CARTONS

When various products need to be packed, the Fast Pecker can be equipped with a quick-change system for grippers. A gripper can simply be disconnected via clamps and a new gripper can easily be attached. At high speeds, a quick-change system for cartons is provided so that the infeed of products does not have to be stopped when changing from a full box to an empty box.

TECHNICAL

The Fast-Pecker is made up of 4 axes: three arms and a rotation axis. The three arms come together in one point on which the gripper or quick-change system is mounted. By rotating the arms, the gripper takes the desired position.

Due to the constantly changing load and high speed of the Fast Pecker, extremely high dynamic forces occur. That is why the Delta robot is built into a welded portal frame consisting of thick-walled profile tubes of 150 x 150 mm. This results in a very sturdy structure that absorbs the continuous forces of the robot.

At the top against the portal frame, a flange is welded to which the manipulator is attached. Fencing is mounted between the pillars of the portal frame that prevents people from accessing the whole during operation and could thus come into contact with the moving robot. At the positions where the operator needs access, doors are foreseen in the fencing. Operation is done via a large color display.